Biotech in Focus: India’s Biomanufacturing Momentum and Fermbox Bio’s Role in Precision Fermentation

As India’s bioeconomy rises, Fermbox Bio builds platform-driven biomanufacturing to deliver scalable, real-world industrial biotech solutions.

The shift is clear- biotech is no longer a lab story. It’s becoming infrastructure for how we make things, cleanly and at scale. And we’re building for that.”

BANGALORE, KARNATAKA, INDIA, August 1, 2025 /EINPresswire.com/ -- As the global demand for sustainable, tech-enabled alternatives intensifies, biotechnology is emerging as a critical industrial engine. In India, this shift is particularly visible through the rise of modern biomanufacturing, backed by a strong talent pool, improving infrastructure, and focused government attention. At the heart of this momentum is a new generation of biotech companies building with scale, science, and sustainability in mind—among them, Fermbox Bio. — Preeti Dharmagoudar, Co-founder, Fermbox Bio

Anchored in precision fermentation and enzyme engineering, the company focuses on building scalable platforms that deliver real-world industrial impact, reimagining how bio-based production can serve sectors like chemicals, fuels, food ingredients, and nutrition.

“The next phase of biotech is execution at scale—turning validated science into industrial production,” says Mr. Subramani Ramachandrappa, Founder, Fermbox Bio. “India brings together scientific depth, manufacturing experience, and an active technology ecosystem, creating a strong foundation for globally scalable biomanufacturing.”

Enabling Ecosystem, Expanding Ambition:

India’s bioeconomy is poised for transformative growth—on track to reach $300 billion by 2030, up from about $165 billion today (1).

Looking further ahead, India is set to become one of the top three global bio-economies by 2040, playing a key role in biopharmaceuticals, bio-based chemicals, and precision fermentation—driven by both domestic scale and meaningful export growth (2).

This surge is backed by a wave of capital: government programs like Bio‑RIDE under the Bio E3 Policy, state-backed biotech schemes, and the continued rollout of manufacturing-linked incentive (PLI) programs are reducing entry barriers. Meanwhile, private investment, marquee venture capital funds, and international R&D partnerships are driving scale and innovation—especially in areas like cell and gene therapies, industrial biotech, and precision fermentation.

The country’s advantage lies not just in scale but in integration— science, robust process know-how, and access to large domestic and global customer base allows companies like Fermbox Bio to build with both depth and speed.

Platform-Driven Biomanufacturing:

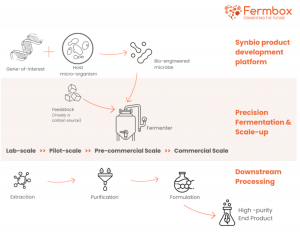

At Fermbox Bio, biomanufacturing is approached as a platform capability—driven by its Full Stack Biotech Product Platform—Bio-ARC Platform, a combination of strain and enzyme engineering, process development, feedstock flexibility, and real-time scale-up expertise.

This platform approach is particularly crucial in precision fermentation. It reprograms microbial metabolism by integrating strain, enzyme, and process engineering. The system-level design enables production of structurally complex molecules—from enzymes and proteins to complex small molecules—with precision, yield stability, and process robustness.

By collapsing development silos early, it de-risks scale-up and creates a predictable path from genetic construct to industrial output.

Precision Fermentation: A Cross-Industry Enabler:

Precision fermentation is a biotechnology process where microbes—such as yeast, bacteria, or fungi—are programmed to produce specific ingredients: proteins, enzymes, or small molecules. Instead of growing plants or raising animals to extract these components, precision fermentation enables direct production in fermentation tanks—similar in principle to brewing beer or yogurt, but with far greater control over the output.

Inside a precision fermentation unit, custom-engineered microbes—refined through strain and enzyme engineering—serve as living factories for your target compound. In the upstream phase, these strains are cultured from bench-scale fermenters all the way to full-scale bioreactors under tightly controlled pH, temperature and dissolved-oxygen conditions.

While the term seems modern, the core technology is not new. Microbial fermentation has been used for decades in biopharma and nutrition industries to manufacture amino acids, vitamins, APIs and therapeutic proteins at industrial scale. What’s changed is the toolset. Advances in strain engineering, enzyme optimization, computational modelling, and process integration have accelerated development timelines, lowered production costs, and expanded the application space into new sectors such as fuels, materials, cosmetics, and food ingredients.

This approach is now gaining traction across industries because it offers cleaner, more efficient, and highly scalable manufacturing routes. Precision fermentation is delivering commercially viable solutions with measurable sustainability impact across product portfolios including - animal-free dairy proteins, enzymes for turning agricultural residues into fuels, or bio-based alternatives to petrochemical ingredients.

Fermbox Bio is applying this model to solve real-world sustainability challenges. Its early products are targeted at sectors like second-generation (2G) ethanol and agro-waste valorization (EN3ZYME), with additional solutions under development including—industrial enzymes and bio-based colors, dyes, flavors and fragrances. These are not niche or experimental use cases—they are designed to integrate into existing, large-volume supply chains.

With a platform built for customer co-development, Fermbox Bio aligns product design with market demand. R&D teams work closely with manufacturing partners to rapidly prototype, validate, and scale solutions, creating a faster path from lab to commercial application.

As industries accelerate efforts to decarbonize and secure supply chains, precision fermentation is emerging as a scalable, cross-sector solution—and Fermbox Bio is building the integrated platform to drive that shift.

Looking Ahead: Global Potential, Local Strength:

As the world pushes toward climate-conscious industrial models, countries like India are well positioned to offer both capability and cost advantage. For Fermbox Bio, this means continued investment in platform innovation, enabling multi-region manufacturing capacity, and deepening strategic partnerships in Asia, Europe, and the Americas.

SOURCES (Published online):

1. India’s Bio‑Economy Set to Hit $300 Billion by 2030: Report

2. India’s Transformation Through to 2040: Overview of the Metrics of Industrial India vs Information‑Age India

Neelima Dandapat

Fermbox Bio Pvt Ltd

email us here

Visit us on social media:

LinkedIn

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.